The semiconductor supply crunch: what’s it about and what does it mean for you?

The world is facing a shortage of semiconductors. Saloni Sardana explains why the world has run out of them and why the chip shortage will ripple across dozens of industries.

Get the latest financial news, insights and expert analysis from our award-winning MoneyWeek team, to help you understand what really matters when it comes to your finances.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Twice daily

MoneyWeek

Get the latest financial news, insights and expert analysis from our award-winning MoneyWeek team, to help you understand what really matters when it comes to your finances.

Four times a week

Look After My Bills

Sign up to our free money-saving newsletter, filled with the latest news and expert advice to help you find the best tips and deals for managing your bills. Start saving today!

Microchips – or semiconductors – are used in the production of a huge range of products, from cars to computers, fridges and much more.

Right now, the world is facing an acute shortage which is wreaking havoc for many companies. At the same time, demand is peaking, leading to supply chain issues for a number of sectors.

Tesla’s Elon Musk recently likened the current semiconductor shortage to the great toilet paper drought at the start of the Covid crisis. “Our biggest challenge is supply chain, especially microcontroller chips. Never seen anything like it”, he said.

MoneyWeek

Subscribe to MoneyWeek today and get your first six magazine issues absolutely FREE

Sign up to Money Morning

Don't miss the latest investment and personal finances news, market analysis, plus money-saving tips with our free twice-daily newsletter

Don't miss the latest investment and personal finances news, market analysis, plus money-saving tips with our free twice-daily newsletter

In a sign that the world’s largest economy is getting increasingly worried about the supply chain issues related to microchips, US president Joe Biden this week announced he will establish a “supply-chain disruptions task force” to address supply chain shortage in a number of crucial fields.

So why is the world running short on semiconductor supply and who all does it affect? Here’s a broad summary of the story so far.

What are semiconductors and why are they important?

Semiconductors form the backbones of most modern electronic equipment. They are usually made of silicon and, as their name implies, they conduct an electrical charge more than an insulator, such as ceramic, but less than a true conductor such as metal.

Controlling their electrical conductivity means they can be used to switch or amplify electrical signals, and can be used to form integrated circuits, memory chips and microprocessors.

Any disruption in the supply of semiconductors could halt production across multiple industries worldwide. This is because the supply of chips cannot be easily increased or decreased at a stroke. Changing the production line can be a lengthy process and takes weeks or even months.

Why is there a shortage?

In the early days of the covid pandemic, staff at microchip production plants in China and globally were unable to work. And, as the world locked down, the lack of demand forced many microchip producers to shutter operations or operate at very low capacity.

But while Covid-19 lockdowns caused lower demand for some industries, others, such as laptop manufacturers, saw a surge in demand for products as much of the world moved to working from home. So demand for microchips bounced back faster than many producers anticipated, bringing us to where we are today.

On top of all that, a series of unfortunate events around the world worsened the situation. A fire broke out at a plant near Tokyo belonging to chip supplier Renesas; Texas suffered an unusually cold spell earlier this year; and Taiwan saw the worst droughts in its 56-year history.

Why are car producers so heavily affected by the chip shortage?

The car manufacturing industry is highly dependent on semiconductors. As Dan Hearsch, managing director in AlixPartners’ automotive and industrial practice points out, the automotive industry uses more chips than other sectors; chips are necessary for basic functions of vehicles, including power steering and brakes, to operate.

“There are up to 1,400 chips in a typical vehicle today, and that number is only going to increase as the industry continues its march toward electric vehicles, ever-more connected vehicles and, eventually, autonomous vehicles”, he says.

The chip shortage has forced some major vehicle-makers to leave some features out of the vehicles they produce. Nissan reportedly excluded navigation systems out of some of its completed vehicles, and Renault stopped offering an oversized digital screen behind its steering wheel, reports Bloomberg.

Both Ford and General Motors have warned of huge losses in the coming year due to supply chain issues. Ford expects the chip shortage to hammer its earnings by around $2.5bn in 2021, while General Motors is bracing for losses in the range of $1.5bn-$2bn. Consulting firm AlixPartners has warned the global chip shortage will reduce the global vehicle industry’s revenue by $110bn in 2021.

Apart from the automotive industry, all consumer technology industries are highly vulnerable to the shortage. Goldman Sachs expects it to have ripple effects across 169 industries in some way or another, reports Yahoo Finance.

When is the semiconductor shortage expected to end?

Most market watchers expect the shortage to persist at least until early next year. Flex, the world’s third-largest manufacturer, warned last weekend the shortage will last until at least mid-2022. Goldman Sachs was more upbeat, suggesting that the chip shortage will dissipate in the second half of 2021.

“Our analysts believe we’re probably in the worst period of that right now. That is, we’re seeing the biggest disruption downstream (in) industries like auto right now and that will gradually ease over the back half of the year,” Andrew Tilton, the bank’s chief Asia economist told CNBC this week.

Rising Covid cases in Asian countries such as South Korea, Vietnam and Taiwan could lead to further supply chain issues and worsen the shortage of chips. But Tilton doesn’t think the situation has caused a significant shortfall in production.

How will the shortage affect investors?

A shortage in semiconductors means many producers could pass on the cost of higher raw materials (due to scarcity) on to consumers, which may be inflationary.

But at the same time, the shortage also means chip producers could be more profitable than ever. Bank of America is recommending Qualcomm for its “high margin royalty business”, Analog Devices for its “diverse product lines”, and Qorvo for its “diverse 5G handset exposure with solid infra (infrastructure) portfolio,” reports CNBC.

Will there be a supply glut later on?

While most of the world is worried about a shortage of chips, the lead time – how long it takes to get a chip once ordered – may actually be a sign that a supply glut in microchips may follow.

Bloomberg reported in March that microchips are witnessing higher lead times. So there is the risk that the supply chain issues force companies to “over order” and also the risk that the world is left with too many microchips which may then result in the opposite story: a crash in the price of microchips. Time will tell.

Get the latest financial news, insights and expert analysis from our award-winning MoneyWeek team, to help you understand what really matters when it comes to your finances.

Saloni is a web writer for MoneyWeek focusing on personal finance and global financial markets. Her work has appeared in FTAdviser (part of the Financial Times), Business Insider and City A.M, among other publications. She holds a masters in international journalism from City, University of London.

Follow her on Twitter at @sardana_saloni

-

Should you buy an active ETF?

Should you buy an active ETF?ETFs are often mischaracterised as passive products, but they can be a convenient way to add active management to your portfolio

-

Power up your pension before 5 April – easy ways to save before the tax year end

Power up your pension before 5 April – easy ways to save before the tax year endWith the end of the tax year looming, pension savers currently have a window to review and maximise what’s going into their retirement funds – we look at how

-

The enshittification of the internet and what it means for us

The enshittification of the internet and what it means for usWhy do transformative digital technologies start out as useful tools but then gradually get worse and worse? There is a reason for it – but is there a way out?

-

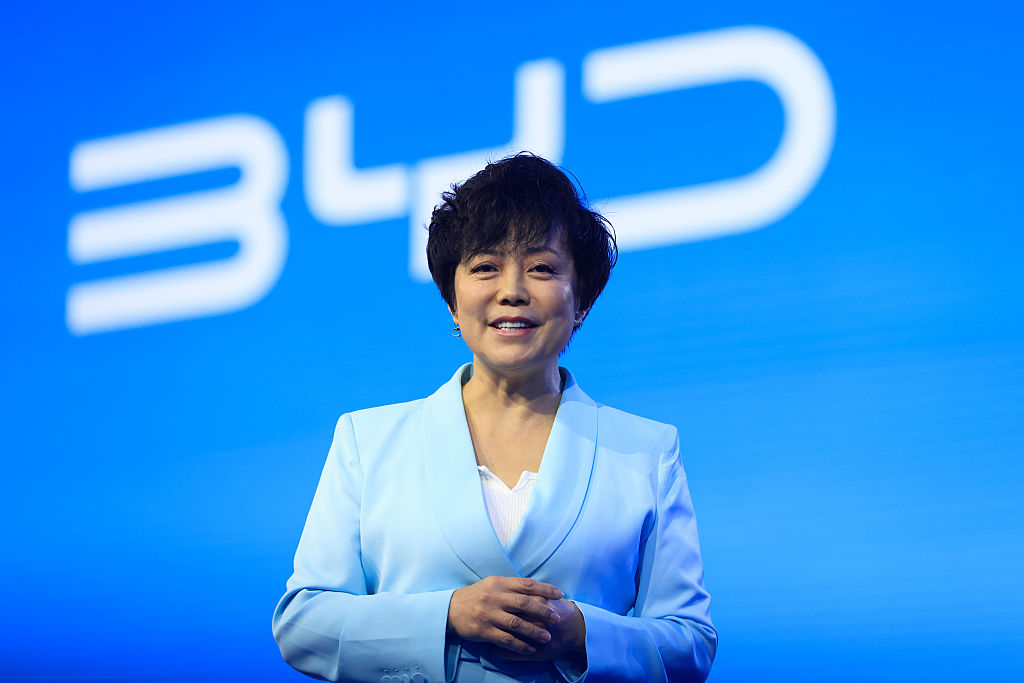

The Stella Show is still on the road – can Stella Li keep it that way?

The Stella Show is still on the road – can Stella Li keep it that way?Stella Li is the globe-trotting ambassador for Chinese electric-car company BYD, which has grown into a world leader. Can she keep the motor running?

-

What's behind the big shift in Japanese government bonds?

What's behind the big shift in Japanese government bonds?Rising long-term Japanese government bond yields point to growing nervousness about the future – and not just inflation

-

UK wages grow at a record pace

UK wages grow at a record paceThe latest UK wages data will add pressure on the BoE to push interest rates even higher.

-

Trapped in a time of zombie government

Trapped in a time of zombie governmentIt’s not just companies that are eking out an existence, says Max King. The state is in the twilight zone too.

-

America is in deep denial over debt

America is in deep denial over debtThe downgrade in America’s credit rating was much criticised by the US government, says Alex Rankine. But was it a long time coming?

-

UK economy avoids stagnation with surprise growth

UK economy avoids stagnation with surprise growthGross domestic product increased by 0.2% in the second quarter and by 0.5% in June

-

Bank of England raises interest rates to 5.25%

Bank of England raises interest rates to 5.25%The Bank has hiked rates from 5% to 5.25%, marking the 14th increase in a row. We explain what it means for savers and homeowners - and whether more rate rises are on the horizon