How to invest in the chipmakers fixing the semiconductor shortage

Last year’s chip crunch brought home how dependent the world is on these tiny pieces of silicon. Chipmakers are rushing to build new factories. Will they turn a shortfall into a glut? Alex Rankine reports

Get the latest financial news, insights and expert analysis from our award-winning MoneyWeek team, to help you understand what really matters when it comes to your finances.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Twice daily

MoneyWeek

Get the latest financial news, insights and expert analysis from our award-winning MoneyWeek team, to help you understand what really matters when it comes to your finances.

Four times a week

Look After My Bills

Sign up to our free money-saving newsletter, filled with the latest news and expert advice to help you find the best tips and deals for managing your bills. Start saving today!

The world doesn’t have enough semiconductors. Over the past year shortages of these tiny pieces of silicon have had big consequences. Car assembly lines have been halted for want of chips; video gamers have found it almost impossible to acquire the latest consoles; politicians have been fretting about national security – it hasn’t escaped their notice that 92% of the world’s most advanced chips are made by just one firm: Taiwan Semiconductor Manufacturing (TSM).

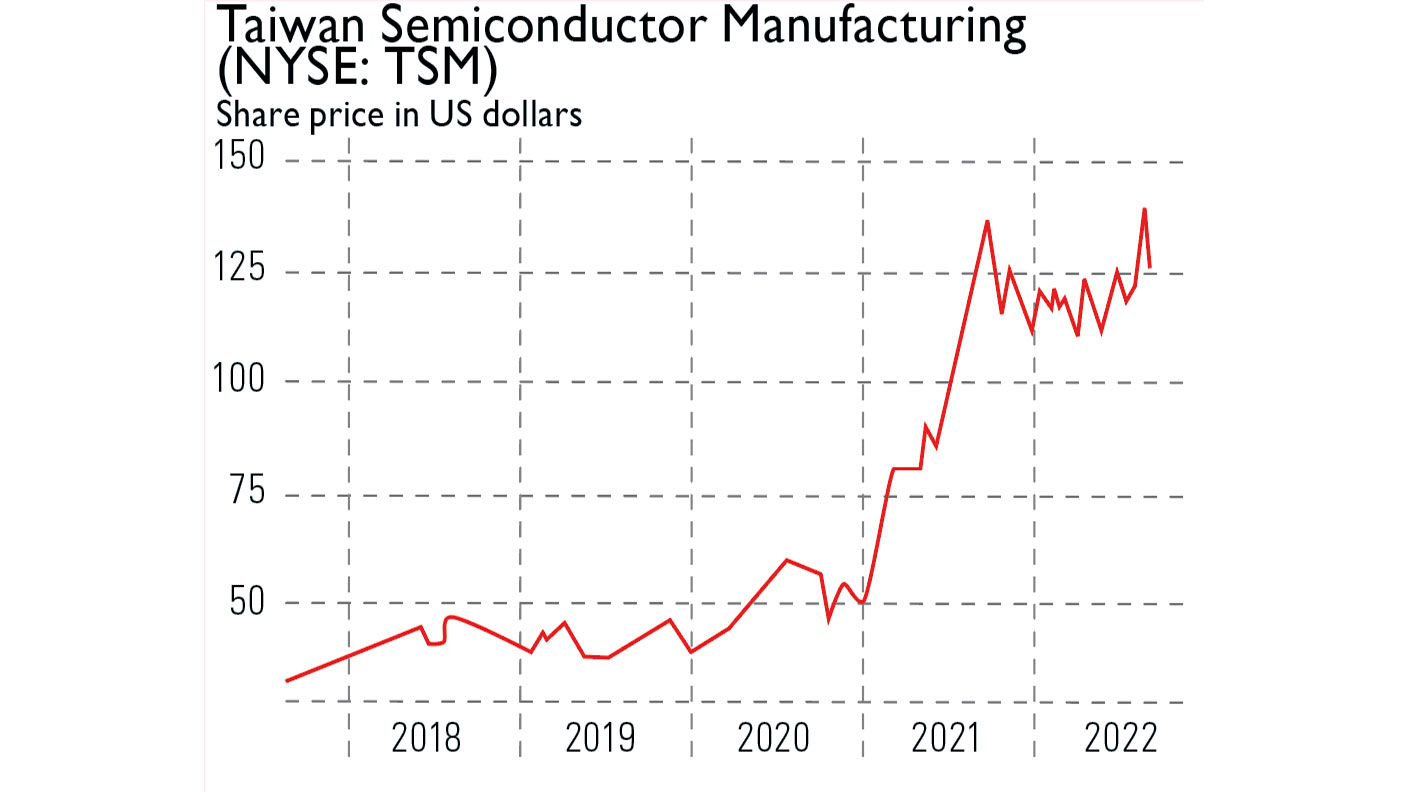

Meanwhile, investors have been in the money. The PHLX Semiconductor Index, which tracks the industry’s leading lights, gained 43% last year. However, as firms rush to build new factories, some question whether the industry is about to go from shortages to an impending glut.

A technological marvel

Semiconductors play a central role in powering today’s economy. Modern life would certainly be impossible without them. Most consumers think about chips, if at all, when acquiring a new laptop or a phone. A newer chip means better graphics and a snappier performance. But the sophisticated “system on a chip” that powers a smartphone represents only a fraction of the global market. Vast numbers of microcontrollers and sensors are needed to keep everything from 5G masts to fridges to electric toothbrushes running. Pets are microchipped in case they go missing. The global car industry has been hit hard by shortages because modern cars need upwards of 100 chips to power everything from the steering to the parking sensors. Such sensors play a growing role in “smart manufacturing” too – more data helps a firm to optimise its production lines.

MoneyWeek

Subscribe to MoneyWeek today and get your first six magazine issues absolutely FREE

Sign up to Money Morning

Don't miss the latest investment and personal finances news, market analysis, plus money-saving tips with our free twice-daily newsletter

Don't miss the latest investment and personal finances news, market analysis, plus money-saving tips with our free twice-daily newsletter

Semiconductors are made from silicon, the second-most abundant element on earth. After being mined from silica-rich quartz, it is refined into a wafer, a flat, shiny disc that is about the size of a dinner plate. This is then shipped off to a fabrication plant. A speck of dust is enough to disrupt the delicate task of etching the circuits, so processing happens in a room that is kept far cleaner than an operating theatre.

An intricate, microscopic web of transistors is etched into the wafer by machines that seem to come straight out of science fiction. A semiconductor crams billions of transistors onto a slice of silicon about the size of a ten-pence piece. Apple’s M1 Max chip, which is used in high-end laptops, has 57 billion of them (the human brain, for reference, hosts about 86 billion neurones). Each transistor is just nanometres in size, about 10,000 times thinner than a human hair.

The highest end chips are made using a lithography machine that “generates a specific wavelength of high-energy ultraviolet light by blasting molten drops of tin with a laser 50,000 times a second”, says Clive Thompson in the MIT Technology Review. Such extreme ultraviolet (EUV) is “devilishly hard to manipulate”. Wavelengths are so short that they are absorbed by air, meaning the whole thing must happen in a vacuum. Only one company in the world, the Dutch firm ASML, produces the machines. The “size of a small bus”, each can cost up to $150m.

A wafer goes through hundreds of processing steps as it is repeatedly heated, blasted with a laser and measured until the design in achieved. The wafers are tested (despite the precautions, a certain percentage are always defective and must be thrown away). Finally, the individual chips are cut out of the wafer and packaged ready for use.

The cutting edge of design

Greater numbers of transistors require ever more miniaturisation – smaller chips are more efficient and can pack more circuits onto a wafer, which reduces production cost. Chips are categorised by the nominal size of their transistors (although today this is more of a marketing label than an exact measurement). Higher numbers mean less advanced technology: 28nm chips were at the cutting edge in 2013, powering the latest Xbox. Today they are more likely to be found keeping your Wi-Fi running. Today’s leading “process” is the 5nm chip. Just two companies – TSMC and Samsung in South Korea – are able to produce them.

Leading-edge chips attract all the attention, but they only account for about 11% of the output of contract chip makers like TSMC. Simpler memory chips, sensors and microcontrollers make up the bulk of the market by volume. These widgets have been running especially short of late, says Wired. A simple power-controlling integrated circuit, usually priced at $1, “can now sell for as much as $150”, according to Josh Pucci of Sourceability. Lead times for simple components have gone from four to eight weeks up “to 24-52 weeks”, according to IC Insights.

Even humble analogue chips are hard to find, says Yang Jie in The Wall Street Journal. Rather than using binary code, such chips “treat incoming information about temperature, sound and electrical current more like a human would, on a scale with many gradations.” Such chips might be used to stop a battery overheating or power a phone display. Last year, laptop maker Asustek’s assembly line suffered stoppages, apparently because of “a lack of analogue chips costing a few dollars apiece”.

The chips are down

Before the pandemic, semiconductors were going through a rough patch. The last chip cycle had peaked in 2018, with sales falling back 12% in 2019, according to data from the Semiconductor Industry Association. The pandemic looked like another blow: carmakers cancelled their orders, anticipating a fall in vehicle demand. Instead, lockdowns drove an unprecedented surge in sales of consumer electronics and work-from-home office equipment. Sales were up an estimated 25.6% year-on-year in 2021, making semiconductors into a half-a-trillion-dollar industry.

Semiconductors are highly cyclical. On the demand side, when supply is tight many customers double orders to be sure they have enough supplies. That makes it difficult for chipmakers to gauge the true level of demand. “Phantom orders” stalk the nightmares of the industry’s executives. On the supply side, contract foundries – firms that make chips for anyone – cannot respond immediately to higher demand. It takes about two years and several billion dollars to construct a new fabrication plant (“fab”). By the time new capacity comes online, it is often too late.

The latest crisis has triggered a rush of new investment. Up to 29 new fabs are expected to be built worldwide during the two years to the end of 2022, says a report from Deloitte. That could take global manufacturing capacity up by 36% compared to the start of 2020. TSMC raised capital expenditure 66% on the year in 2021 to $30bn. Industry analysts think global chip supplies will remain tight at least for the first half of this year, but come 2023 we could be heading for a chip glut. While supplies of leading 3nm, 5nm and 7nm should remain fairly tight, less advanced chipmakers could be heading for trouble.

Much of the new capacity is in the 22nm to 90nm range, says Nikkei Asia. There are signs that the chip cycle has already turned for memory chips, with prices falling during the four months to November last year. But others argue that the industry stands to benefit from major structural tailwinds. The rollout of 5G, electric vehicles and smart devices in homes and factories will see demand for all types of chips soar over the next decade. The rise of cloud computing and artificial intelligence are other big opportunities for semiconductors. “It took 50 years for the industry to grow to half a trillion dollars today, and now it is estimated that the industry will grow to a trillion in roughly eight years”, said Tom Caulfield, CEO of GlobalFoundries, the world’s fourth-biggest foundry, as work on its new Singapore fab began last year.

It remains to be seen whether Caulfield is right. Alarmed about their dependence on distant suppliers, governments have been lavishing subsidies on the industry. America is spending $52bn to encourage more domestic semiconductor manufacturing, with Intel and TSMC planning to open new US plants. The EU is pushing for “digital sovereignty”, with a plan to double the continent’s share of the business by the end of the decade. China wants to be 70% self-sufficient in chips by 2025. That will require massive investment. The country only sourced 16% of the chips it needed domestically in 2020, according to IC Insights. Surprisingly few chips are “Made in China”.

Growing subsidies and protectionism are likely to distort the market. Today’s semiconductor supply chain is highly specialised, says Ma Tieying of DBS in a recent note. “If many countries attempt to establish their domestic semiconductor supply chain encompassing all segments, it could result in lower efficiency and higher costs in the long run.”

Absolutely fabless

Semiconductor manufacturing is highly concentrated. Roughly 80% of chips are made in northeast Asia. TSMC alone accounts for more than half of chip manufacturing, followed by Samsung’s foundry division with 17%. The likes of Taiwan’s UMC, GlobalFoundries (an American firm with Singaporean roots) and China’s SMIC specialise in producing less advanced “trailing-edge” chips.

Today most semiconductor firms have gone “fabless”, meaning that they design the chips but contract out production to a foundry. Many prominent names, from US graphics card specialist Nvidia to communications giants Broadcom and Qualcomm do not make their own chips. While foundries are increasingly concentrated, design is competitive. AMD and Nvidia vie for graphics card supremacy, while Qualcomm and Taiwan’s Mediatek square off for dominance of the mobile market.

The shift towards “fabless” production has been driven by steeply rising costs. Cramming ever more transistors onto a chip approaches the limits of physics. That doesn’t come cheap. Capital expenditure in the industry more than doubled in the decade to 2020 at $109bn, according to data from Statista. TSMC’s latest leading edge fab will cost more than $19bn to build. Unable to keep pace, most firms have dropped out of the foundry game.

A giant comes unstuck

Only a handful of firms still operate the traditional integrated model, designing and fabricating their own chips. The most prominent is Samsung, but it runs the foundry business at arm’s length from its other operations. Others are niche players, such as analogue specialist Texas Instruments. Intel, the firm that created the microprocessor, has also stuck with the model, but that has proved a failing strategy. While TSMC and Samsung march ahead with 5nm chips, Intel, long the industry leader, has struggled to keep up. It delivered its 10nm chip five years late and won’t release a 7nm chip until 2023. That has forced it to outsource some chip manufacturing to its Asian rivals.

The company was caught flat-footed by the rise of smartphones, which use different designs to the ones with which the company had long dominated the PC market. Now even Intel’s position there is coming into question, as Apple ditches the firm’s chips in favour of its own designs for Macs (these chips will be made by TSMC). The share price has fallen more than 16% over the past year, even as the wider chip industry soars. New CEO Pat Gelsinger has launched a turnaround, with plans to let the design and fabrication arms operate more independently. That is more in line with how Samsung does things. Yet rather than doing that as a first step to spinning off the foundries, Gelsinger is doubling down on them.

Intel has been splashing the cash, announcing new multi-billion-dollar developments in Arizona and Ohio. Flush with subsidies from Brussels, it plans to spend $95bn on building several European plants over the next decade. Gelsinger claims to “have more concrete trucks working for me today than any other human on the planet”. There are plenty of sceptics: Intel will struggle to match TSMC’s vast capital outlays. The company has a long track record of overpromising and underdelivering on new chips. But Gelsinger is nothing if not confident. He wants to regain “unquestioned leadership” in semiconductors by 2025. His secret weapon? A chip with transistors so minute that they measure just 20 angstroms across – the next unit down beneath the nanometre.

Big names and niche players

It’s a brave move to bet on a turnaround at Intel (Nasdaq: INTC). A return to industry leadership looks a long shot. Still, the firm is positioned to benefit from growing protectionism. Western governments will increasingly insist that chips destined for military and other sensitive applications are manufactured in the west. That could create rather a cosy berth for Intel, even if the chips fade into technical mediocrity. On a price/earnings ratio of 10 the shares are astoundingly cheap for a US tech stock.

Broadcom (Nasdaq: AVGO) is also intriguing. This designer of chips for wireless systems stands to gain from the 5G rollout. Broadcom is that rarest of beasts – a tech giant that acts like a FTSE dividend stock. It is highly cash generative, quarterly payouts have grown rapidly over the past decade, and the shares are yielding almost 3%.

TSMC (NYSE: TSM) is the pick of the foundries. No other firm can match its enormous capital spending, which gives it a solid moat against any rivals hoping to eat its lunch. The main risks are geopolitical. Trouble in the Taiwan Strait could make last year’s chip shortage look like a walk in the park.

Nvidia (Nasdaq: NVDA) designs chips that are ideal for the booming areas of artificial intelligence and cloud computing. That’s reflected in a price/earnings ratio of 72. The firm seems set to abandon its bid to buy mobile chip designer ARM, which may be an attractive option if ARM’s owner Softbank responds by disposing of it through an initial public offering (IPO).

Dutch lithography giant ASML (Amsterdam: ASML), Europe’s star semiconductor business, has cornered the market in extreme ultraviolet (EUV) lithography. It’s a one-of-a-kind stock and that’s reflected in a p/e ratio of 52. Sales are forecast to grow 20% this year.

Germany’s Infineon (Frankfurt: IFX) and Franco-Italian STMicroelectronics (Paris: STM) specialise in automotive and power semiconductors. This is a growth area thanks to electric vehicles (EVs). STMicroelectronics provides cutting-edge silicon carbide technology to Tesla, but Infineon is snapping at its heels.

Investors can also look at some of the less well-known firms that support the industry. Lam Research (Nasdaq: LRCX) sells specialist equipment to help chip manufacturers improve production yields and reduce defects. Applied Materials (Nasdaq: AMAT) provides many of the non-lithography tools needed to make microchips. Longtime competitor Tokyo Electron (TYO: 8035) should benefit from similar trends. Singapore’s UMS Holdings (Singapore: 558), which supplies tools to Applied Materials and Intel supplier AEM (Singapore: AWX) are much smaller stocks that also stand to gain from a rise in capital spending.

A few ETFs offer broad exposure to the market. These include Lyxor MSCI Semiconductors ETF (LSE: SEMG), an ESG-screened fund with an ongoing expense ratio of 0.45%, and VanEck Vectors Semiconductor ETF (LSE: SMH), on an ongoing expense ratio of 0.35%.

Get the latest financial news, insights and expert analysis from our award-winning MoneyWeek team, to help you understand what really matters when it comes to your finances.

Alex is an investment writer who has been contributing to MoneyWeek since 2015. He has been the magazine’s markets editor since 2019.

Alex has a passion for demystifying the often arcane world of finance for a general readership. While financial media tends to focus compulsively on the latest trend, the best opportunities can lie forgotten elsewhere.

He is especially interested in European equities – where his fluent French helps him to cover the continent’s largest bourse – and emerging markets, where his experience living in Beijing, and conversational Chinese, prove useful.

Hailing from Leeds, he studied Philosophy, Politics and Economics at the University of Oxford. He also holds a Master of Public Health from the University of Manchester.

-

Average UK house price reaches £300,000 for first time, Halifax says

Average UK house price reaches £300,000 for first time, Halifax saysWhile the average house price has topped £300k, regional disparities still remain, Halifax finds.

-

Barings Emerging Europe trust bounces back from Russia woes

Barings Emerging Europe trust bounces back from Russia woesBarings Emerging Europe trust has added the Middle East and Africa to its mandate, delivering a strong recovery, says Max King

-

Barings Emerging Europe trust bounces back from Russia woes

Barings Emerging Europe trust bounces back from Russia woesBarings Emerging Europe trust has added the Middle East and Africa to its mandate, delivering a strong recovery, says Max King

-

How a dovish Federal Reserve could affect you

How a dovish Federal Reserve could affect youTrump’s pick for the US Federal Reserve is not so much of a yes-man as his rival, but interest rates will still come down quickly, says Cris Sholto Heaton

-

Three companies with deep economic moats to buy now

Three companies with deep economic moats to buy nowOpinion An economic moat can underpin a company's future returns. Here, Imran Sattar, portfolio manager at Edinburgh Investment Trust, selects three stocks to buy now

-

Should you sell your Affirm stock?

Should you sell your Affirm stock?Affirm, a buy-now-pay-later lender, is vulnerable to a downturn. Investors are losing their enthusiasm, says Matthew Partridge

-

Why it might be time to switch your pension strategy

Why it might be time to switch your pension strategyYour pension strategy may need tweaking – with many pension experts now arguing that 75 should be the pivotal age in your retirement planning.

-

Beeks – building the infrastructure behind global markets

Beeks – building the infrastructure behind global marketsBeeks Financial Cloud has carved out a lucrative global niche in financial plumbing with smart strategies, says Jamie Ward

-

Saba Capital: the hedge fund doing wonders for shareholder democracy

Saba Capital: the hedge fund doing wonders for shareholder democracyActivist hedge fund Saba Capital isn’t popular, but it has ignited a new age of shareholder engagement, says Rupert Hargreaves

-

Silver has seen a record streak – will it continue?

Silver has seen a record streak – will it continue?Opinion The outlook for silver remains bullish despite recent huge price rises, says ByteTree’s Charlie Morris